Flexographic Printing

The Go-To Solution for Versatile and High-Volume Packaging Needs

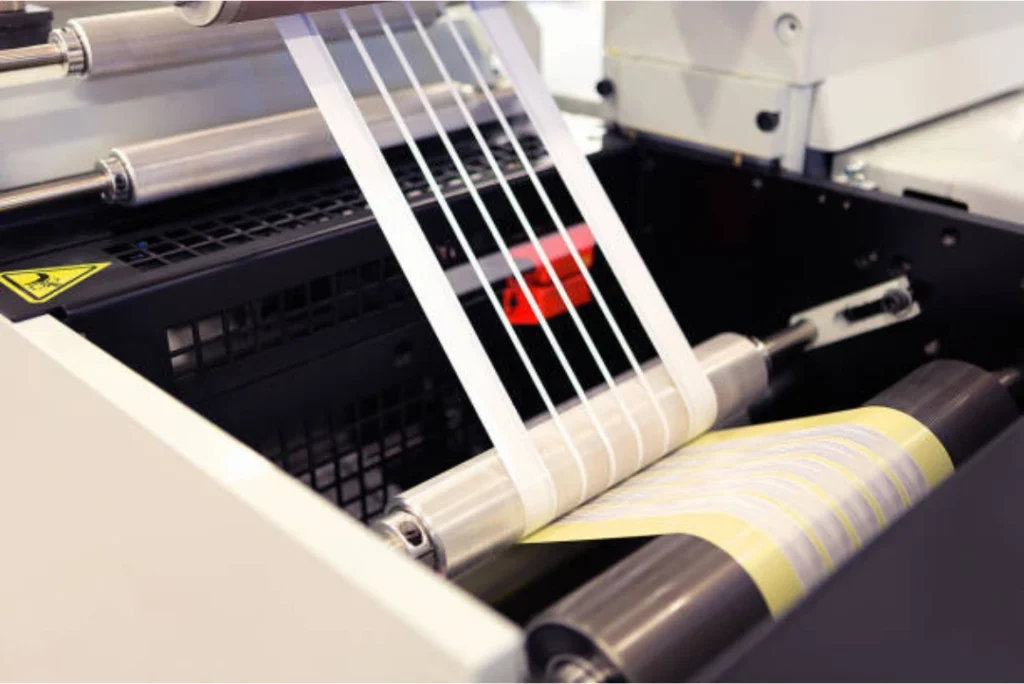

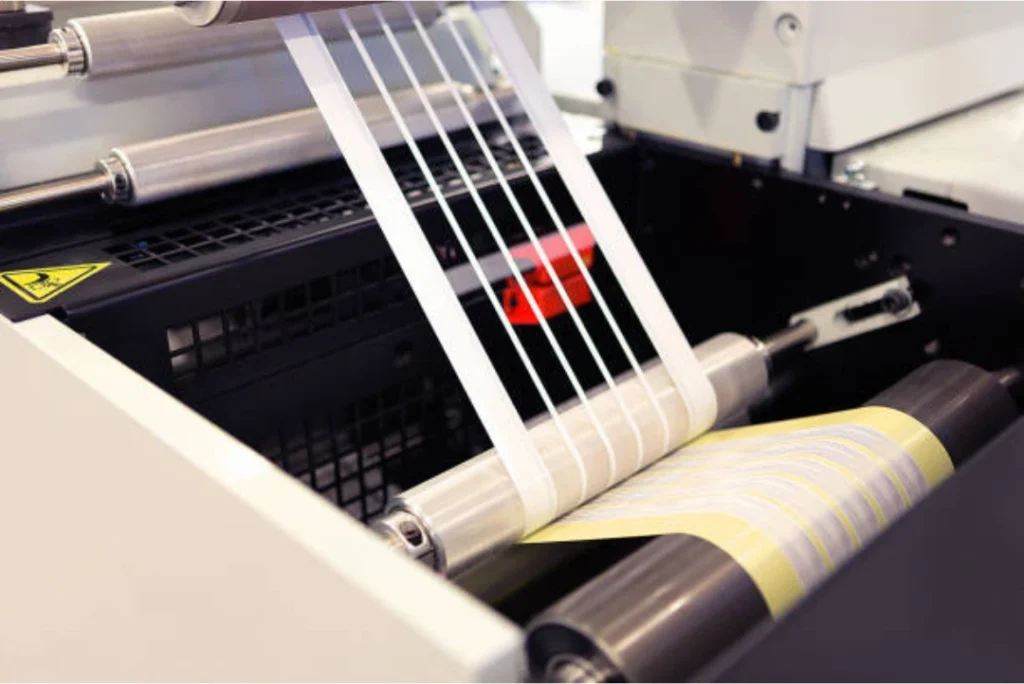

Flexographic printing, often called flexo printing, is a highly versatile and efficient method designed for printing on a wide range of materials. Unlike traditional methods like litho printing, flexography is tailored for flexible substrates such as plastics, corrugated cardboard, paper, foil, and films, making it the preferred choice for packaging, labels, and continuous patterns on rolls.

What sets flexo printing apart is its adaptability and speed. Using flexible relief plates, this method can quickly produce vibrant, high-quality prints on non-flat surfaces, such as shrink wraps, food packaging, and even custom labels for curved containers. With fast-drying, low-viscosity inks, it’s particularly suited for high-volume production where speed and efficiency are critical.

Flexo printing also shines in its ability to print directly onto materials like kraft paper, cardboard, and even metallic films without the need for additional coatings or processes. This allows businesses to achieve a polished, professional look while keeping costs manageable. Whether it’s printing barcodes, branded packaging, or intricate designs, flexography delivers consistent, durable results that withstand the demands of retail and transportation.

For businesses in industries like food, beverage, retail, and logistics, flexo printing provides a practical and scalable solution for packaging and labeling needs. Its ability to handle diverse materials and high-volume orders makes it a standout choice for creating visually striking and functional packaging that represents your brand at its best.

FAQs About Flexographic Printing

General Overview

Flexographic printing, or flexo printing, is a versatile printing technique that uses flexible relief plates to transfer ink onto a wide variety of surfaces. It’s commonly used for packaging, labels, and other materials.

Flexo printing is ideal for producing labels, corrugated boxes, flexible packaging, plastic bags, food wrappers, and other high-volume packaging materials.

The process involves using flexible printing plates wrapped around rotating cylinders. Ink is applied to the plate, which then transfers the design onto the material as it passes through.

Flexo printing offers high-speed production, the ability to print on a wide range of materials, vibrant colors, and cost-efficiency for large print runs.

Materials and Compatibility

Flexo printing works on paper, cardboard, plastic films, foil, and other flexible substrates commonly used in packaging.

Yes, flexographic printing supports eco-friendly materials like biodegradable films and recycled paper to meet sustainable packaging needs.

Flexo printing is best suited for flexible and smooth surfaces. Textured or rigid materials may not be compatible.

Design and Customization

Flexographic printing handles both simple and complex designs, including logos, patterns, and intricate graphics.

Yes, flexo printing supports Pantone color matching, ensuring accurate and consistent brand colors across print runs.

Yes, we can help you create or adapt your designs for optimal results with flexographic printing.

Flexographic printing delivers sharp and vibrant prints, though it may have slightly less fine detail compared to lithographic or digital printing.

Sizes and Applications

Flexo printing can handle a wide range of sizes, from small labels to large flexible packaging rolls.

Yes, flexo printing is highly customizable and perfect for tailored packaging solutions like branded bags, boxes, and wrappers.

Absolutely. Flexo printing uses food-safe inks and materials, making it ideal for printing on food packaging like wrappers, bags, and cartons.

Yes, flexo printing is well-suited for adding variable data, such as barcodes, QR codes, and expiration dates, directly onto the material.

Ordering and Production

Flexographic printing is most cost-effective for high-volume orders, with typical MOQs starting at 1,000 units or more.

Production times vary based on the size and complexity of the order but usually range from 1-3 weeks.

Pricing depends on factors like material, design complexity, and quantity. Contact us for a custom quote tailored to your project.

Yes, but separate printing plates are required for each design, which may impact costs.

Durability and Usage

Flexo prints are highly durable and designed to withstand handling, shipping, and environmental exposure, depending on the chosen materials and finishes.

Yes, flexographic printing can use inks and finishes that provide water and weather resistance, ideal for outdoor or refrigerated packaging.

Yes, we can create durable, reusable packaging solutions using flexographic printing.

Miscellaneous

Yes, flexo printing supports specialty finishes, including metallic inks, varnishes, and textures, to enhance your packaging design.

Flexographic printing is the perfect choice for high-volume, cost-effective packaging and label solutions that require vibrant, durable prints on a variety of materials.